|

High quality carbon and steel bars are used in our plant to produce grinding steel balls. After being rolled, red hot steel balls are conveyed into special heat treating equipment at once for online heat treatment. By doing so, homogeneous hardness and better wearablilty can be obtained. In addition, steel balls can be reheated in our heat treating workshop according to particular requirement.

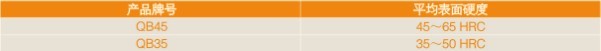

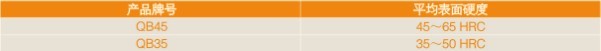

1、AVERAGE SURFACE HARDNESS

Those who were produced with the “haverage surface hardness” are characterized by its harder surface, larger and softer core as well as good elasticity and anticracking features. Normally the diameter range of this kind of product is 60~130mm.

Product grades and hardness values are as follows:

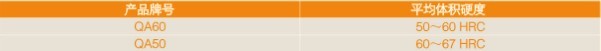

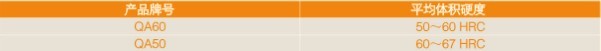

2、AVERAGE VOLUMETRIC HARDNESS

Product produced according to average volumetric hardness?has a uniform high hardness throughout its volume thus maintain good wear properties down to very small diameters. Normally the diameter range of this kind is 20~80mm.

Product grades and hardness values are as follows:

In general"average volumetric hardness"is considered to give a better indication of wear Performance.

Hardness values of balls are determined by making and testing samples according to the national standard of China HRC Hardness Testing Method for Metals (GB230-80).

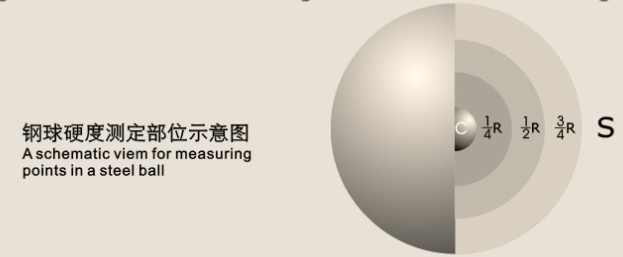

The average surface hardness of balls is measured in the way below:

First, determine the hardness values at 4 random points on the surface of each sample; secondly, get the arithmetic average as the average surface hardness of this sample.

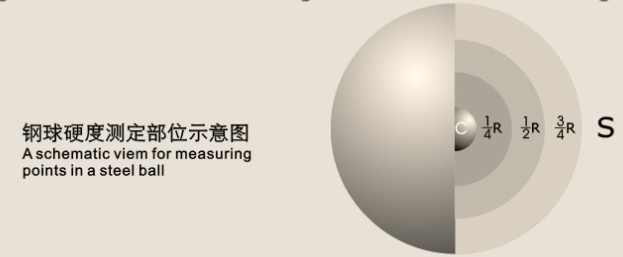

The average volumetric hardness of steel balls is measured in the way below:

To determine the hardness values at 5 points of each sample. One of these points is on the surface and other 4 are placed respectively on 3/4 R, 1/2 R, 1/4 R and the center on the same section of the sample. Then the average volumetric hardness of balls can be calculated from the following formula:

A.V.H.= 0.289×surface hardness

+0.437×hardness at 3/4 R

+0.203×hardness at 1/2 R

+0.063×hardness at 1/4 R

+0.008×center hardness

We have proved that when the value is higer than 544VHN (500 BHN), It is proper to use RCHN method to measure the hardness of grinding media.

|