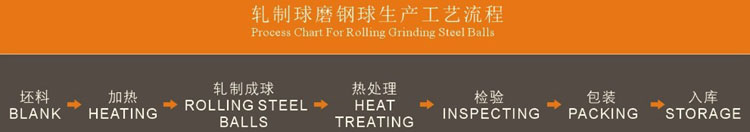

Process Flow

|

||||||||

| 1、The blank used for producing the grinding steel balls is hot rolled bar with various kinds of chemical composition. Its diameter is the same as the nominal diameter of steel balls. 2、Before getting rolled, bars are reheated to a proper temperature in a continuous reheation furnace. 3、After a red hot bar is conveyed into the skew rolling mill, it rotates forward between two rolls with special spiral passes. As this process continues, it is gradually rolled into steel balls. A single skew rolling mill can produce 60~360 steel balls per minute. 4、And then, the hot steel balls are transported directly to the online heat treatment equipment, designed specially for quenching and tempering. Steel balls can obtain very high and uniform hardness. 5、Finished steel balls characterised by the precise dimension and geometry, better wearibility and mechanical properties. 6、The products which passed inspection are transported to the finished product storehouse and then dilivered to users after being packed. It's high quality carbon/alloy steel bars (hot rolled or continuous cast in various specifications) that are used for making grinding media, The diameter of bars should be equal to the nominal diameter of hot rolled balls. Normally, the length of each bar is 2.5-4m.

Our plant can adjust the above chemical composition according to users' requirement, and balls with special requirement, and balls with special grade appointed by users can be produced as well. |

||||||||

|

|